Lightweight FRP/GRP Sandwich Panels for Cleanroom Walls and Doors

1. General Information FRP (Fiberglass Reinforced Plastics) sandwich panels is made of fiberglass skins on both sides and core materials in between. The skin and core material is bonded together by highly adhesive polyurethane glue. For fiberglass skin, we supply gel coated surface and rough...

Product Introduction

1. General Information

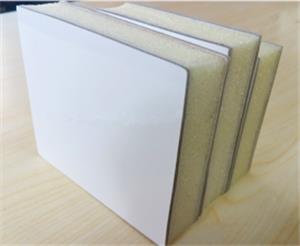

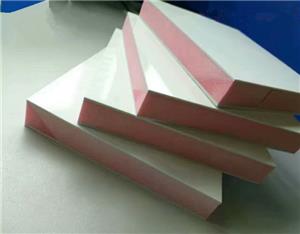

FRP (Fiberglass Reinforced Plastics) sandwich panels is made of fiberglass skins on both sides and core materials in between. The skin and core material is bonded together by highly adhesive polyurethane glue.

For fiberglass skin, we supply gel coated surface and rough surface. Gel coated FRP honeycomb panels are usually used to make cargo truck bodies, while rough surface panel is for further lamination. Core materials can be aluminum honeycomb, PP honeycomb, foam board (XPS, PU, PET, PVC) and plywood. FRP composite panels are highly durable, cost effective and widely applicated.

The max size is 2300mmx10000mm, thickness ranges from 6mm--200mm, any size within this can be customized as per your requirements.

2. Available Specifications:

Regular thickness | 15mm, 18mm, 20mm, 25mm, 30mm |

Regular thickness of FRP | 1.2mm, 1.5mm, 2.0mm,2.5mm |

Regular panel size | Standard size 4x8ft 1220x2440mm, Max. size 2300x10000mm |

Panels for truck body | 20mm or 25mm thick |

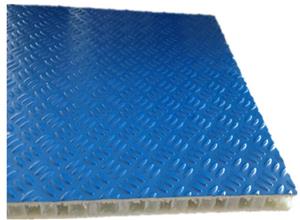

The composite panels for truck body are usually 20mm or 25mm thick, with 2mm FRP on each side and 16mm PP honeycomb as core. The panels used for floors is made with checkered skins for anti-slip purpose. Panels used for refrigerated truck body are usually 50mm thick with PU foam inside due to good heat insulation.

We manufacture panels of different types with different materials according to your specific needs. Let us know your requirements and we will give suggestions and professional help.

3. FRP sandwich panel range

|  |

| FRP PP Honeycomb Panel | FRP PP Honeycomb Panel |

|  |

| FRP Plywood Sandwich Panel | FRP PU Foam Sandwich Panel |

|  |

| FRP XPS Foam Sandwich Panel | Anti-slip FRP Sandwich Panel |

4. Features:

Light weight

High strength

Heat insulation

Sound and Vibration Dampening

Water, moisture, corrosion and chemical resistant

Environmental protection

No deformation, No decolor, long life circle

Low thermal conductivity

Easy to install

4. Applications:

Construction - platform in scaffold, stadium bleachers, exhibitions and stages

Ships and yachts - interior wall panels, roof, freezer, deck, etc.

Automobiles interior decorations, van body walls and so on

Logistic Various kinds of boxes and containers

Commercial truck floor panel

Food-processing plants, aquatic products processing plant

Cold room partition, doors, Cleanroom partition, doors

5. Packaging & Delivery

Covered with protective film, then piled and packed in export grade plywood crates.

Delivery Time: 15 to 30 days depend on order quantity

You Might Also Like

-

PE or PVDF Prepainted Aluminium Honeycomb Sandwich Panels with 15 Year Warranty

-

Decorative Building Materials Wood Color Aluminum Honeycomb Panels for Wall Facades

-

Non Skid Aluminum Honeycomb Panels for Stage Floors

-

Fireproof High Pressure Laminate with Aluminum Honeycomb Panels for Marine Decoration

-

Wood Grain PVDF Coated Single Aluminum Panel for Commercial Building

-

Heat Insulation FRP PU Sandwich Panels for Cold Room Walls

Send Inquiry